TO ACCESS MORE DATA YOU NEED TO LOGIN

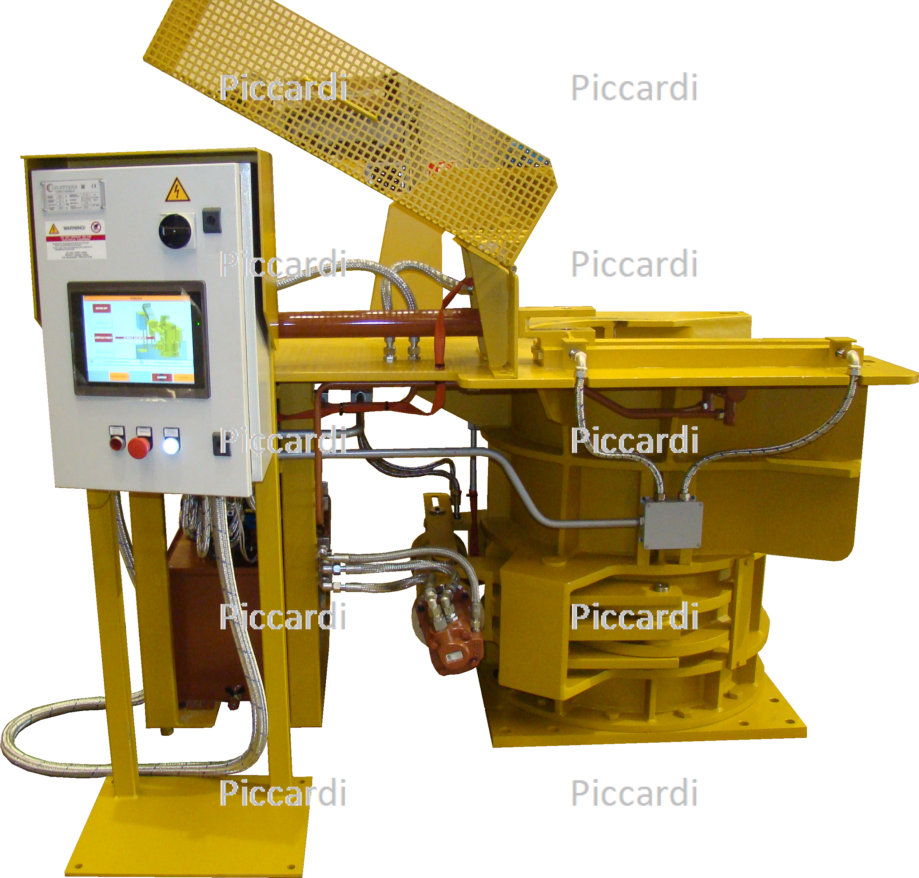

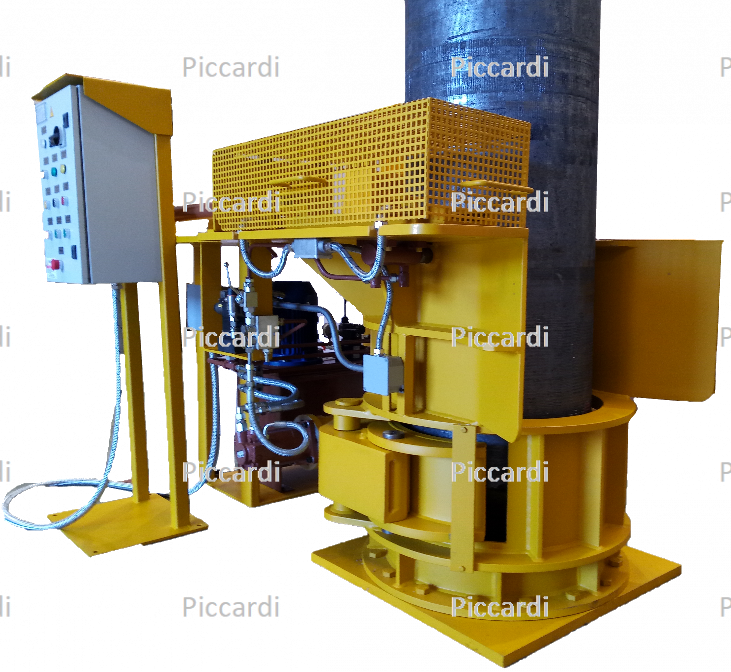

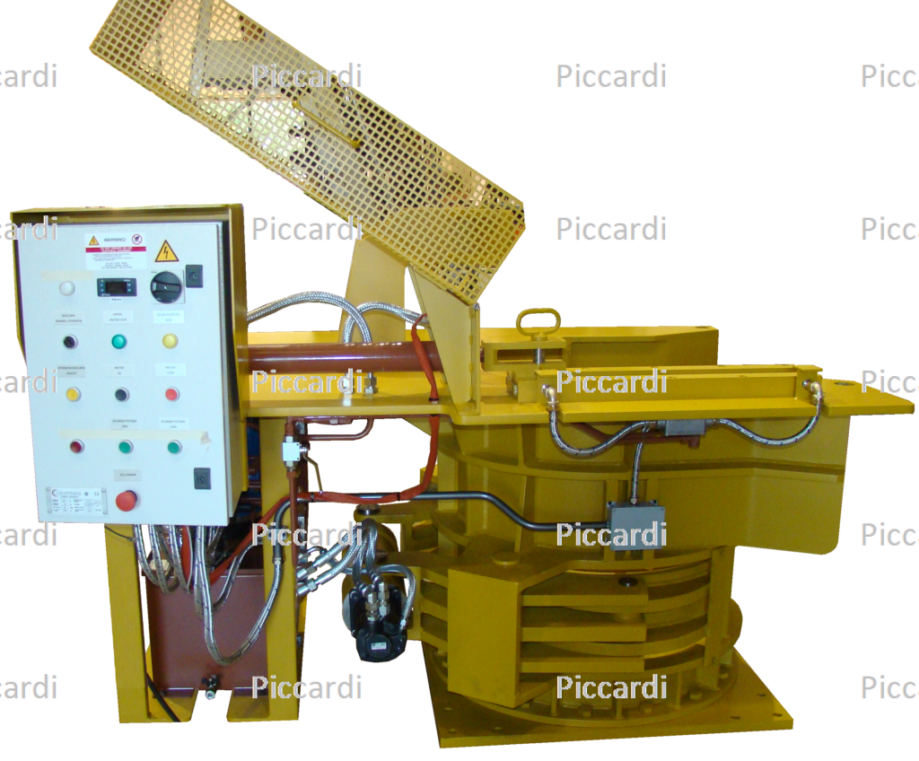

ITEM 26 – Torque Station for Graphite Electrodes

An intelligent hydraulic machine for the assembly of graphite electrodes:

- Once the clamps are closed they cannot be opened unintentionally (any oil leakage does not involve the mechanical screw). Clamps can hold the electrode column for extended periods.

- The U-shape gives the possibility of approaching very easily sideways to the column with the new electrode.

- The side opening allows the lifting plugs to be removed quickly and easily.

- A lever-clamping collar and a cylinder are supplied, to achieve a correct assembly and set the required torque.

- This system allows the unscrewing of previously jointed electrodes.

- The electrode joining operation is driven by a PLC and requires only one operator.

- Automatic tightening sequence is provided.

- A display shows the tightening torque achieved at the end of the operation.

Standard Version

- Manual distributor for clamps opening and closing.

- Tightening push buttons to control the machine.

- Digital display for instant torque monitoring.

Gold Version

Provided with a Touch Panel which allows to:

- control the movements of the station (all push buttons are digital)

- show the information about the device

- show all the information about the tightening process, including the last torque reached

- diagnostic features including alarm messages, input and output states

- the remoted electrical board could be installed far from the electrodes area and, if necessary, interlocked with a restricted area to enhanced safety